Fighter jets can refuel in flight, saving much time on long trips. So, what if you could likewise top off your vehicle’s energy supply while zooming along?

That is the vision of Khurram Afridi, associate professor of electrical and computer engineering at Cornell University.

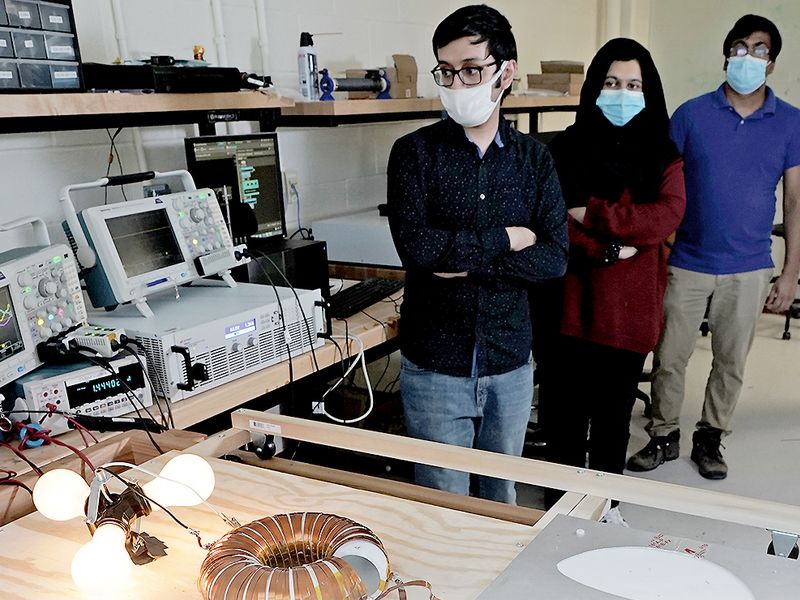

Afridi’s team is exploring a way to charge moving electric vehicles as they pass over high-voltage wires embedded in the roadway. It’s known as dynamic wireless power transfer.

The team’s approach uses capacitive charging with high-frequency (13.56 megahertz) electric fields, vs. the lower-frequency (85 kilohertz) magnetic fields used in the inductive charging pads on the market today, which require a vehicle to remain stationary while being charged.

Imagine, no waiting in line. No getting out at a station and fumbling with cash or a credit card in the dark, rain, heat or snow. And critically, EV batteries could be much smaller, improving sustainability and vehicle performance and greatly enhancing fire safety.

Effectively, this less expensive, faster, safer EV of the future might never stop just to charge.

“That’s really where the motivation for this comes from,” says Afridi. “You’re dealing with lithium, which is a relatively rare material. It can catch fire. And it is not an easy fire to put out. A recycling infrastructure needs to be put in place. And battery cost will remain a consideration, even though the cost has come down. Something like 30 to 40 percent of an EV’s cost is the battery. And this enables driverless cars. You do not need a driver to stop and plug something in. It’s really a game changer in that sense.”

But what does a dynamic wireless power-transfer system even look like?

“That is an excellent question,” says Afridi. “And that is essentially the question still being debated. It is being debated in the sense that there are many possible solutions. They can be higher power and short distance, or they can be lower power and longer distance.” They might also use either magnetic or electrical fields, he says.

For a century, academics at places such as Stanford University and Oak Ridge National Laboratory and industry researchers at companies such as Qualcomm and WiTricity Corp. have been trying to crack the tech problems and high cost of wirelessly charging an EV using guided magnetic fields.

Those challenges include the use of ferrite, a fragile and expensive material; concerns about exposing passengers to electromagnetic fields; and the risk of the charging pad accidentally heating up nearby metal objects.

Afridi, however, believes a more practical and affordable system might use electrical fields instead. Recent cost-reduction and technical breakthroughs in power electronics, near-field coupler designs and semiconductor materials such as exotic gallium nitride could make it easier to pull off. Afridi’s promising work with electrical fields at Cornell has hit its targets and attracted funding from the Advanced Research Projects Agency – Energy and the National Science Foundation.

Today, automakers such as Renault and BMW are starting to roll out stationary commercial EV charging stations that are wireless; charging a battery to 80 percent takes 30 to 40 minutes.

But Afridi says that charging moving vehicles is more complicated and involves vastly higher and faster power transfers. He estimates commercial electrical-field EV charging might be 10 or even 15 years away. But he feels that now is the time for discussion and development as the U.S. government plans massive infrastructure investments, world EV markets surge and auto companies announce multibillion-dollar EV investment plans.

With dynamic wireless power transfer, either capacitive or inductive, the vehicle’s receiving unit quickly moves past the sending unit embedded in the road. A vehicle might be on a half-mile-long charging grid for 30 seconds or less. So, both types require sophisticated power electronics, such as a high-frequency inverter and rectifier.

So far, only experimental roadways for wireless magnetic-field power transfer have been built. And these prototypes have consistently proved to be complicated, fragile and expensive.

Estimates by different experts and companies range from $600,000 to $2.5 million a kilometer, depending on individual configurations and requirements.

“It may be possible that the magnetic field system’s economics will not work out,” Afridi says. “The capacitive system is a lot cheaper in principle. If nobody deploys the magnetic-field system in the next three to five years, we may just skip the magnetic-field systems all together and go directly to the electric-field system.”