The transistors used in vehicle power electronics are conventionally made from silicon. But GaN Systems Inc. of Ottawa is moving forward on transistors made from a hard crystal known as gallium nitride, or GaN, created by combining gallium with nitrogen.

GaN Systems believes the material change will enable smaller, more efficient and lower-cost power electronics, translating to smaller and lighter batteries for electric vehicles with improved charging performance and greater range for vehicles.

BMW AG and other auto and parts manufacturers are interested.

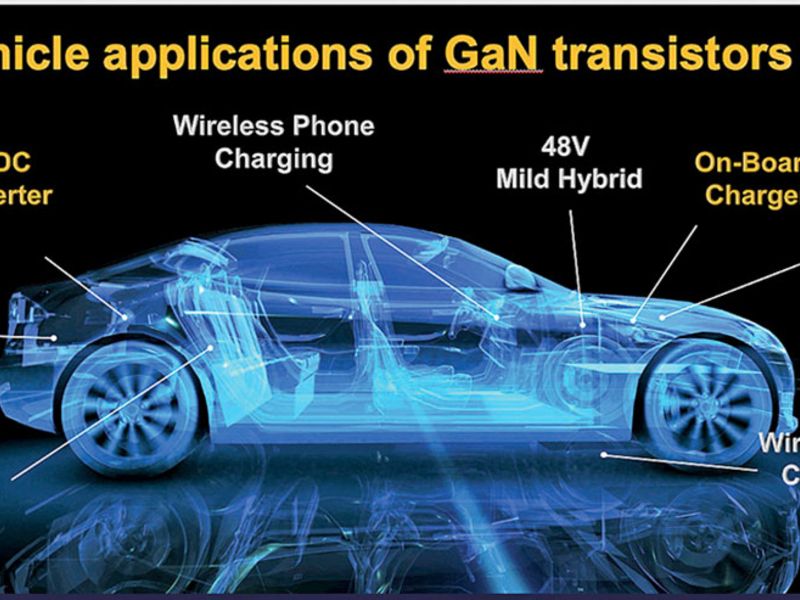

Last month, the luxury automaker signed a deal with GaN Systems to potentially source power transistors for its on-board vehicle chargers and e-motors. The innovation could help BMW produce EVs with higher power density, faster charging capabilities and longer range. The material could also advance capabilities in autonomous driving and wireless power applications.

For the past 13 years, GaN Systems has primarily supplied its gallium nitride-based transistors to the consumer electronics and data center industries. But it is now following the money and shifting its focus as the electrifying auto industry seeks out transistors for a new generation of power systems.

Its automotive customers include Toyota, EV startup Canoo and supplier Hella.

The internal combustion engine vehicle has about $100 worth of power electronics, vs. $400 in an electric vehicle, GaN Systems CEO Jim Witham told Automotive News.

“The 55 million EVs expected to be on roads globally in 2040 will require $22 billion worth of power electronics,” Witham said.

Semiconductor materials have what is called a “band gap” that determines how well a solid material can conduct electricity. Gallium nitride has a band gap expressed as 3.4 electron volts, compared with silicon’s 1.12 eV band gap.

The wider band gap means it can sustain higher voltages and higher temperatures than silicon, making it suitable for high-power and high-frequency devices such as EV drive units.

A more efficient semiconductor will mean that less energy is expended as heat, enabling smaller power systems to do the job with lower material costs.

“We can cut the size and the weight of the power electronics,” Witham said. “If the car is lighter, then your range extends.”

For instance, GaN Systems said its power semiconductors can shrink an on-board charger by about one-third its current size. This contributes to decreased vehicle weight, enabling longer driving range.

Energy-efficient power systems also mean automakers can reduce the number of batteries needed — a major cost driver in an EV.

GaN Systems claims its power transistors can save EV makers $1.1 billion in lower materials and battery costs and increase driving range by 6 percent.

Prior to its deal with the supplier, BMW’s venture capital arm, BMW i Ventures, invested in GaN Systems in 2017. At that early stage, Uwe Higgen, BMW i Ventures’ managing director at the time, described gallium nitride transistors as “the next big steppingstone in miniaturization.”

BMW also now sees demand for energy-efficient transistors increasing as automakers need data centers to support autonomous-vehicle development.

“Data center power consumption is one of the biggest cost drivers,” Higgen said at the time of BMW’s outlook. “And increasing the efficiency of power conversion will account for billions of dollars in cost savings.”